PCB Manufacturing

Propelling Rapid, Low Cost 24/7 PCB Production

Spectra-Physics is a leading supplier of lasers for the manufacture of printed circuit boards and microelectronics packaging. Our lasers are proven in a wide range of PCB applications including cutting, depaneling, via hole drilling, direct imaging, trimming, repair and marking. With thousands of lasers deployed in demanding PCB applications, Spectra-Physics delivers a broad portfolio of highly reliable, cost-effective lasers backed by our industry-leading global support organization.

- Powering critical PCB apps: cutting, drilling, LDI, trimming, repair, marking etc.

- Proven in demanding volume production

- Driving highest throughput

- Delivering disruptive cost-performance

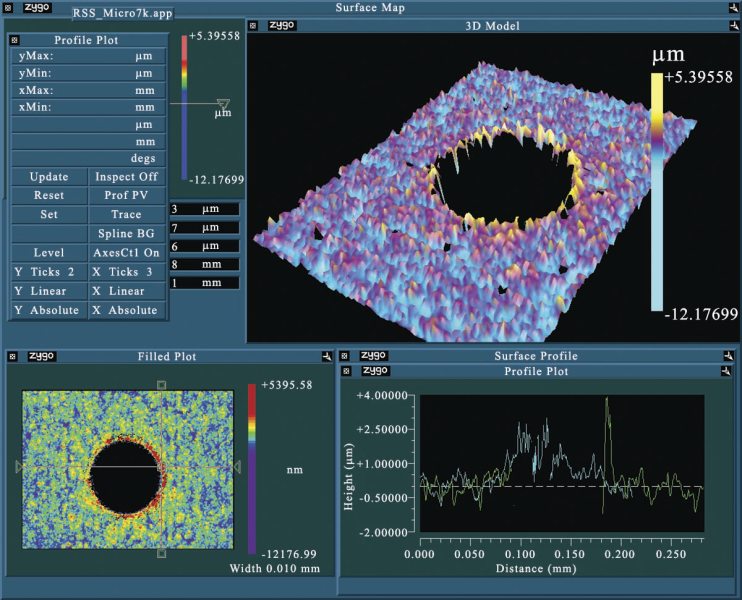

PCB Cutting and Via Drilling

As electronic devices shrink and improve in performance, the need for compact and thin flex-PCBs to which the electronic devices are mounted is growing rapidly. Flex-PCBs are typically made using layers of materials that have several to tens of .m thicknesses. Materials used include copper (Cu) foils, polyimide (PI) sheets, and adhesives that enable the creation of various laminates. A typical flex-PCB material is comprised of a 12 μm thick PI layer laminated between two Cu foils of similar thickness. In flex-PCB fabrication, laser processes may include blind- and thru-via drilling, straight-line and contoured cutting, as well as 2D patterning. Please see Newport.com for additional information on PCB Manufacturing.